Scientists in business

On 24 June, Paul Zomer defended his PhD thesis at the University of Groningen. Zomer used the technological know-how that he acquired during his research at the company HQ Graphene, which he co-owns with Niko Tombros.

It’s worth beginning by noting that Zomer completed his research project five years ago. Being co-owner of a start-up company takes time. ‘Also, I kept doing more measurements, when I should have started writing,’ he says in his office at the Zernike Lab, a hub for spin-off companies at the Zernike Campus.

Together with Niko Tombros, he owns HQ Graphene . ‘We started by making special devices from the 2D materials graphene and boron nitride.’ These devices are used in research, but are difficult to make. ‘Niko saw the opportunity of supplying scientists with ready-made devices and founded the company in 2012.’ Zomer joined him when his contract at the University ended in January 2014. ‘I didn’t want to continue in academic research, so when Niko approached me, I said yes. The alternative would have been to join a large company like ASML. I liked this better.’ Zomer became the co-owner of HQ Graphene.

Experience

Both had worked in the Physics of Nano Devices research group, led by Professor Bart van Wees. The group studies the movement of electrons through graphene; more specifically, electron spins, a quantum mechanical property that has two values (‘up’ and ‘down’) which can be used to transport information. ‘This is done in graphene, the single atom layer of graphite,’ Zomer explains.

The group discovered that spin transport in very thin graphene flakes improved when the thin flakes were sandwiched between similar 2D flakes of boron nitride, which has a crystal structure that is almost identical to that of graphene. Making these ‘sandwiches’ and attaching electrodes for measurements requires a lot of experience, which both Tombros and Zomer have.

Risky

‘We rented the Nano Lab facility at the Faculty of Science and Engineering when we wanted to produce devices,’ says Zomer. They gained clients through scientific conferences and word of mouth. Business was going well; however, making these devices was time consuming and risky. ‘It takes about a day to make one device, but there is a high risk that the device will not work as desired.’ At the same time, ever more labs began acquiring the knowledge to make these devices themselves.

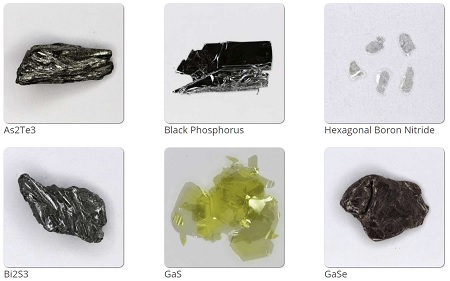

‘That is when we decided to change our approach; we started growing crystals made of other layered materials that were used to make the devices.’ Growing crystals also requires skills and research. ‘Scientists want to work with these materials, not study how to grow crystals.’ And so, the company decided to offer a range of crystals on its website.

Advice

And the group continued to develop its processes even further. Turning the crystals into heterostructure devices requires specialist equipment, such as a microscope and a small heater plate, as well as micromanipulators that allow tiny flakes to be picked up and stacked. Zomer: ‘When I did my PhD project, I built my own system. That took quite a while. Now, we offer complete systems, including the materials you need to start your research as well as free advice.’

So, what is it like to be an entrepreneur in science? ‘Starting a business is associated with some risks, but it also gives a lot of freedom,’ says Zomer. Neither he nor Tombros had any formal training in running a business. ‘Just a short course in economics,’ says Tombros from behind his desk, where he is preparing a FedEx shipment. ‘But all you really need to know is what the demand for your product is and what people are willing to pay.’

Start-ups

When Tombros founded the company, the University couldn’t offer much concrete assistance. ‘The infrastructure was more geared towards start-ups in life sciences,’ he recalls. He visited Delft University of Technology, where getting involved with business is much more common. ‘They have scores of people to advise you there. However, I get the impression that the University of Groningen is now providing more support for start-ups.’ For example, a Professor of Entrepreneurship and Valorization has been appointed, who is also the Dean of the University of Groningen Centre of Entrepreneurship.

Nevertheless, he got the company going and together with Zomer, managed to guide it through those difficult first few years. ‘We learned along the way’, says Zomer. He gives an example. After shipping small packages containing crystals, they started shipping the systems to manufacture devices. ‘These were much larger. And one of them got badly damaged in transit. We learned that we had to secure everything much better.’

Flexibility

The two owners have been careful not to bite off more than they can chew. ‘When we started building these systems, we didn’t advertise a lot – we had to be certain that we would be able to deliver,’ says Zomer. Eventually, they hired their first employee, and recently a second, to help with production and research and development. They need to stay ahead of the game. ‘These 2D materials are developing fast. So, we keep in touch with the scientific world by talking to our former colleagues here and visiting conferences.’ As for the future, the key word is flexibility. ‘We both have families to support,’ concludes Tombros. ‘We want this company to be in business for at least 50 years!’

Interested in starting a company? Check out Business Generator Groningen and University of Groningen Centre of Entrepreneurship

| Last modified: | 30 July 2019 10.38 a.m. |

More news

-

10 June 2024

Swarming around a skyscraper

Every two weeks, UG Makers puts the spotlight on a researcher who has created something tangible, ranging from homemade measuring equipment for academic research to small or larger products that can change our daily lives. That is how UG...

-

21 May 2024

Results of 2024 University elections

The votes have been counted and the results of the University elections are in!