Plastic recycling: with a little help from bacteria

Researchers at the University of Groningen are working on many different types of plastics and what is needed to recycle them. Edita Jurak is looking for bacteria and their enzymes that can help us recycle plastics and clean up the environment. This is the third of four articles on plastic research at the Faculty of Science and Engineering.

FSE Science Newsroom | Text René Fransen

‘I have found bacteria that can live off plastics in lakes here in Groningen,’ says biochemical technologist Edita Jurak. ‘These microorganisms have all the enzymes needed to break down plastics to carbon dioxide and water.’ In applications, Jurak only uses the enzymes without the bacteria as they can work directly on plastic waste. Bacteria would have difficulty ‘eating up’ large pieces of plastic, which needs to happen before the enzymes can do their job.

There are several advantages to using bacterial enzymes for recycling, Jurak explains: ‘They are often cheaper than chemical reagents and more environmentally friendly, as enzymes work best at mild temperatures and don’t require toxic solvents that are often used in chemical processes.’

Why are bacteria eating plastics?

Bacteria have lived on our planet for billions of years, while plastics were first made about a century ago. So, how is it possible that bacteria are able to use plastics as food? Bacteria have lots of genes which produce enzymes to break stuff down and use it as food. It is likely that some of the enzymes that degrade natural food stuffs, such as starches, can also be used to break down plastics, if the chemistry of these reactions is similar. Sugars and plastics are both built out of carbon atoms, which probably explains the plastic-eating bacteria.

It would be possible to use the carbon dioxide that results from the process of breaking down plastics to build new plastics, but another approach is to stop the bacterial enzymes at an earlier stage. ‘It’s more efficient to reuse the broken-down polymer fragments to make new plastics, rather than start again from carbon dioxide.’ However, building new plastics from the fragments that are produced by the enzymes is not straightforward, explains Jurak: ‘Those fragments are often inert: they won’t react unless I first add reactive groups called linkers at the ends of the fragments.’ She can then use other enzymes to rebuild the original plastic, or even produce new plastics with new functionalities from the fragments.

Like her colleague Francesco Picchioni, who uses chemical reactions to recycle plastics, Jurak uses her enzymes to break down polyvinyl chloride (PVC). ‘I will test enzymes on large and small pieces of this material to see what they do to it. The results will show me how to improve the enzymes in order to break down PVC.’ A major problem in recycling this material is that it will produce hydrochloric acid. However, Jurak even found enzymes that will solve this problem, because they are able to remove the chlorine.

Unnatural enzymes

Edita Jurak applies genetic techniques to find out which bacterial genes make the enzymes that help break down plastics. She can then use these genes to produce the pure enzyme. Using molecular technology, she can also change the genes in order to produce enzymes that are better suited for industrial use, for example in a recycling plant. And it is even possible to adapt the enzymes to produce new types of reactions that are useful in plastic recycling.

For more information about this topic, read 'Creating enzymes for sustainable chemistry'.

Enzymes for medical waste

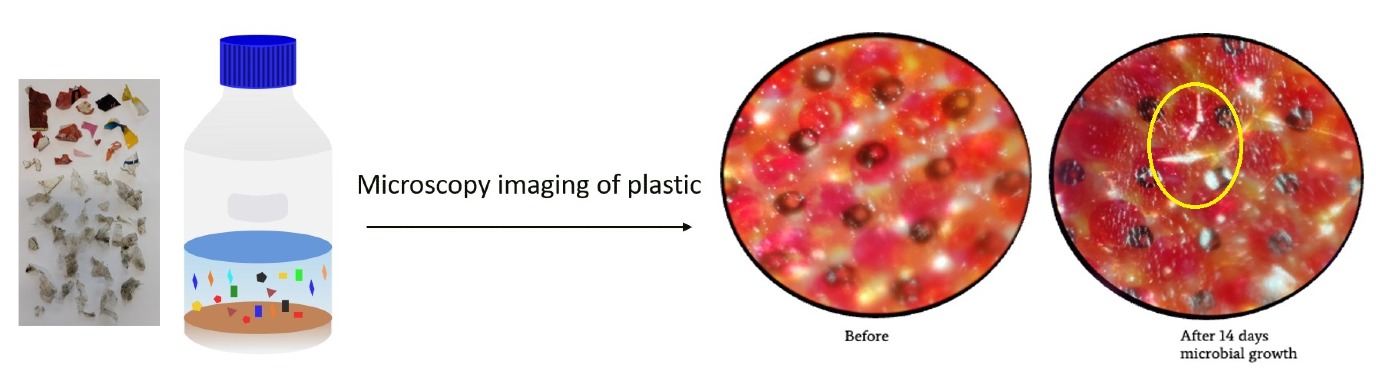

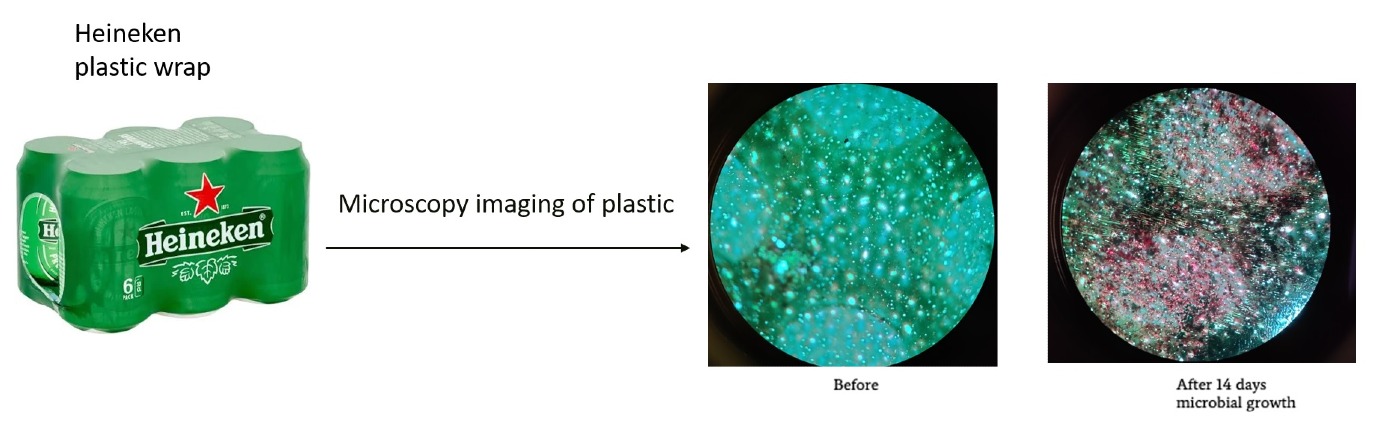

Jurak was also involved in a project to recycle plastic waste from operating rooms at the UMCG hospital. These rooms produce a lot of plastic, such as the packaging for sterile instruments. In addition, all kinds of different plastics are used, resulting in mixed plastic waste. Jurak has been looking for the right bacterial enzymes to break down all the plastics in the mix. ‘They aren’t just different kinds of plastics, but they also contain different additives, such as dyes and stabilizers. So we can’t use one pathway for recycling as all enzymes break down one specific compound. That’s why we need a combination of enzymes.’

All this is complicated, but Jurak is optimistic: ‘We have a lot of proof-of-concept results, so it seems feasible to recycle this material. Even solid pieces of plastics are modified by bacteria, but we still have to understand how they do this.’ A practical problem is that current legislation requires that all waste from operating rooms is incinerated. With the technical challenges and the regulatory changes that are needed, it will take at least another ten years before her techniques can be applied in hospitals. On the positive side: enzymes are already used widely in cleaning products. Washing powders, for example, contain enzymes that break down lipids or proteins.

The bacterial enzymes also have a use outside the hospital. ‘They can be used for bioremediation of soils or lakes polluted with plastics. In fact, we found that this is already happening in nature: the lakes from which we isolated plastic-eating bacteria contain less microplastics.’

This is the third part in a series of four articles on plastics. Next week, you can read about microplastics: how dangerous are they, and what can we do to prevent their production?

| Published on: | 07 April 2025 |

Scientists at the University of Groningen are working on new ways to recycle plastic waste into new, high-quality products.

| Published on: | 31 March 2025 |

University of Groningen scientists have developed new ways to make green plastics, but it is difficult to produce them at competitive prices.

| Last modified: | 15 April 2025 10.18 a.m. |

More news

-

15 April 2025

1.5 million funding from Province of Groningen for innovative technology in the region

The University of Groningen will receive nearly 1.5 million euros in funding from the Province of Groningen to assist entrepreneurial academic researchers in developing innovative ideas into a startup.

-

15 April 2025

Nathalie Katsonis wins Ammodo Science Award 2025

For her pioneering research on molecular systems, Nathalie Katsonis receives the Ammodo Science Award for fundamental research 2025.

-

15 April 2025

Fundamental research with life-size effects

Nathalie Katsonis has won the Ammodo Science Award for Fundamental Research. She develops adaptive molecular materials and studies the chemical origins of life, which in turn yield insights for vaccines and clearing up oil spills at sea.